Pliers

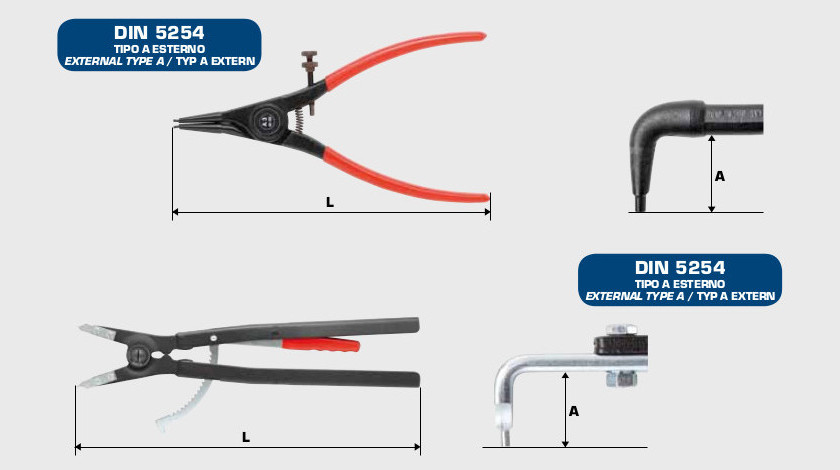

DIN 5254

Plier for retaining rings DIN 471 / DIN 983 / AV / AL

During assembly, the ring is subject to high pressures and it is important to avoid any possible overspread, especially if part is made of stainless steel.

For this purpose, we suggest the use of pliers DIN 5254, provided with stop and return screw and offered with both straight and bent nose.

| RING DIMENSIONS | TIP TYPE | PLIER CODE | TIP Ø mm | WEIGHT gr. ≅ | L | A | OPENING SYSTEM |

|---|---|---|---|---|---|---|---|

| Ø from 3 to 10 mm | straight | AO | 0,9 | 96 | 141 | - | screw |

| bent | A01 | 0,9 | 97 | 130 | 12 | screw | |

| Ø from 10 to 25 mm | straight | A1 | 1,3 | 98 | 141 | - | screw |

| bent | A11 | 1,3 | 97 | 130 | 12 | screw | |

| Ø from 19 to 60 mm | straight | A2 | 1,8 | 186 | 182 | - | screw |

| bent | A21 | 1,8 | 182 | 170 | 14 | screw | |

| Ø from 40 to 100 mm | straight | A3 | 2,3 | 310 | 230 | - | screw |

| bent | A31 | 2,3 | 317 | 210 | 17 | screw | |

| Ø from 85 to 140 mm | straight | A4 | 3,2 | 555 | 320 | - | screw |

| bent | A41 | 3,2 | 563 | 305 | 21 | screw | |

| Ø from 122 to 300 mm | straight | A5 | 3,5 | 1921 | 550 | - | rack |

| bent | A51 | 3,5 | 1898 | 560 | 26 | rack |

Click here to dowload assembly instructions for retaining rings for shafts.