Spring steel EN 10132 - 1/4 (DIN 17222)

Ø from 1,2 to 30 mm: strip

Stainless steel A4 – AISI 316 L (W.N. 1.4404)

Ø from 1,5 to 19 mm: strip

Stainless steel AISI 301 (W.N. 1.4310)

Ø 24 and 30 mm: strip

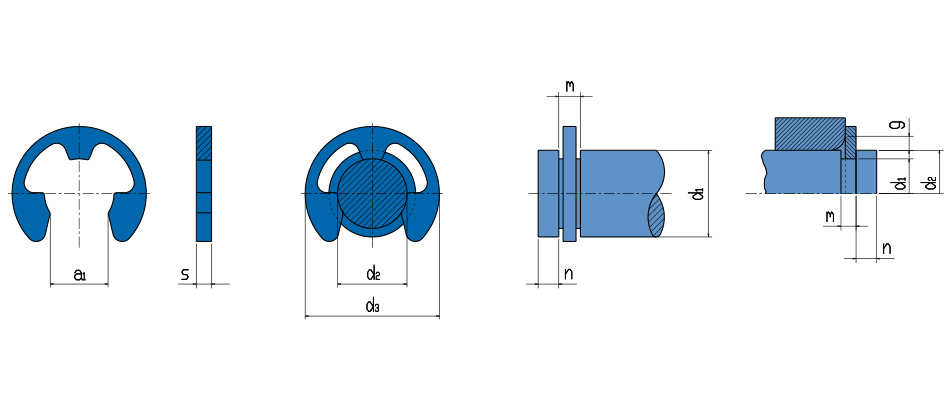

DIN 6799 are radial retaining rings for shafts, which offer wide application possibilities.

They can be assembled by simply pushing them into the slot on the shaft, using the appropriate Assembly Plier.

For an easier and faster mounting by the use of Dispensers and Assembly Pliers, retaining rings type DIN 6799 can be supplied stacked on steel rods.

| SIZE | RING DIMENSIONS | GROOVE DIMENSIONS | SUPPLEMENTARY DATA | WEIGHT | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

d2

h11

|

d3

max

|

s

|

tol

|

a1

|

tol

|

d1

min

|

d1

max

|

m

|

tol

|

n

min

|

FN

kN

|

FN

d1

|

FR

kN

|

g

|

FRg

kN

|

nabl

min ˉ¹

|

Kg/

1000

|

|||

| symbols key | ||||||||||||||||||||

| 1,2 | 3,25 | 0,30 | 0,02 | -0,02 | 1,01 | 0,040 | -0,040 | 1,4 | 2,0 | 0,34 | 0,04 | 0 | 0,6 | 0,04 | 1,5 | 0,12 | 0,4 | 0,06 | 47.000 | 0,007 |

| 1,5 | 4,25 | 0,40 | 0,02 | -0,02 | 1,28 | 0,040 | -0,040 | 2,0 | 2,5 | 0,44 | 0,04 | 0 | 0,8 | 0,07 | 2,0 | 0,22 | 0,6 | 0,11 | 43.000 | 0,018 |

| 1,9 | 4,80 | 0,50 | 0,02 | -0,02 | 1,61 | 0,040 | -0,040 | 2,5 | 3,0 | 0,54 | 0,05 | 0 | 1,0 | 0,10 | 2,5 | 0,35 | 0,7 | 0,17 | 40.000 | 0,027 |

| 2,3 | 6,30 | 0,60 | 0,02 | -0,02 | 1,94 | 0,040 | -0,040 | 3,0 | 4,0 | 0,64 | 0,05 | 0 | 1,0 | 0,15 | 3,0 | 0,50 | 0,9 | 0,24 | 38.000 | 0,060 |

| 3,2 | 7,30 | 0,60 | 0,02 | -0,02 | 2,70 | 0,040 | -0,040 | 4,0 | 5,0 | 0,64 | 0,05 | 0 | 1,0 | 0,22 | 4,0 | 0,65 | 0,9 | 0,32 | 35.000 | 0,074 |

| 4 | 9,30 | 0,70 | 0,02 | -0,02 | 3,34 | 0,048 | -0,048 | 5,0 | 7,0 | 0,74 | 0,05 | 0 | 1,2 | 0,25 | 5,0 | 0,95 | 1,0 | 0,47 | 32.000 | 0,144 |

| 5 | 11,30 | 0,70 | 0,02 | -0,02 | 4,11 | 0,048 | -0,048 | 6,0 | 8,0 | 0,74 | 0,05 | 0 | 1,2 | 0,90 | 7,0 | 1,15 | 1,0 | 0,60 | 28.000 | 0,214 |

| 6 | 12,30 | 0,70 | 0,02 | -0,02 | 5,26 | 0,048 | -0,048 | 7,0 | 9,0 | 0,74 | 0,05 | 0 | 1,2 | 1,10 | 8,0 | 1,35 | 1,1 | 0,70 | 25.000 | 0,231 |

| 7 | 14,30 | 0,90 | 0,02 | -0,02 | 5,84 | 0,048 | -0,048 | 8,0 | 11,0 | 0,94 | 0,05 | 0 | 1,5 | 1,25 | 9,0 | 1,80 | 1,3 | 1,00 | 22.000 | 0,400 |

| 8 | 16,30 | 1,00 | 0,03 | -0,03 | 6,52 | 0,058 | -0,058 | 9,0 | 12,0 | 1,05 | 0,08 | 0 | 1,8 | 1,42 | 10,0 | 2,50 | 1,5 | 1,25 | 20.000 | 0,599 |

| 9 | 18,80 | 1,10 | 0,03 | -0,03 | 7,63 | 0,058 | -0,058 | 10,0 | 14,0 | 1,15 | 0,08 | 0 | 2,0 | 1,60 | 11,0 | 3,00 | 1,6 | 1,50 | 17.000 | 0,904 |

| 10 | 20,40 | 1,20 | 0,03 | -0,03 | 8,32 | 0,058 | -0,058 | 11,0 | 15,0 | 1,25 | 0,08 | 0 | 2,0 | 1,70 | 12,0 | 3,50 | 1,8 | 1,75 | 15.000 | 1,138 |

| 12 | 23,40 | 1,30 | 0,03 | -0,03 | 10,45 | 0,070 | -0,070 | 13,0 | 18,0 | 1,35 | 0,08 | 0 | 2,5 | 3,10 | 15,0 | 4,70 | 1,9 | 2,30 | 13.000 | 1,538 |

| 15 | 29,40 | 1,50 | 0,03 | -0,03 | 12,61 | 0,070 | -0,070 | 16,0 | 24,0 | 1,55 | 0,08 | 0 | 3,0 | 7,00 | 20,0 | 7,80 | 2,2 | 3,30 | 11.000 | 3,119 |

| 19 | 37,60 | 1,75 | 0,03 | -0,03 | 15,92 | 0,070 | -0,070 | 20,0 | 31,0 | 1,80 | 0,08 | 0 | 3,5 | 10,00 | 25,0 | 11,00 | 2,5 | 3,60 | 7.600 | 5,619 |

| 24 | 44,60 | 2,00 | 0,03 | -0,03 | 21,88 | 0,084 | -0,084 | 25,0 | 38,0 | 2,05 | 0,08 | 0 | 4,0 | 13,00 | 30,0 | 15,00 | 3,0 | 4,00 | 5.500 | 8,180 |

| 30 | 52,60 | 2,50 | 0,03 | -0,03 | 25,80 | 0,084 | -0,084 | 32,0 | 42,0 | 2,55 | 0,08 | 0 | 4,5 | 16,50 | 36,0 | 23,00 | 3,5 | 5,30 | 4.200 | 14,440 |

Spring steel EN 10132 - 1/4 (DIN 17222)

Ø from 1,2 to 30 mm: strip

Stainless steel A4 – AISI 316 L (W.N. 1.4404)

Ø from 1,5 to 19 mm: strip

Stainless steel AISI 301 (W.N. 1.4310)

Ø 24 and 30 mm: strip

Spring steel EN 10132 - 1/4 (DIN 17222)

Ø from 1,2 to 30 mm: HV 460 ÷ 580, HRC 46 ÷ 54

Stainless steel A4 – AISI 316 L (W.N. 1.4404)

Ø from 1,5 to 3,2 mm: resistance 1176 ÷ 1274 N/mm² - 120 ÷ 130 Kg/mm²

Ø from 4 to 6 mm: resistance 981 ÷ 1079 N/mm² - 100 ÷ 110 Kg/mm²

Ø from 7 to 8 mm: resistance 931 ÷ 1030 N/mm² - 95 ÷ 105 Kg/mm²

Ø from 9 to 19 mm: resistance 882 ÷ 981 N/mm² - 90 ÷ 100 Kg/mm²

Stainless steel AISI 301 (W.N. 1.4310)

Ø 24 and 30 mm: resistance 883 ÷ 981 N/mm² - 90 ÷ 100 Kg/mm²

Ø 1,2 / 1,5 / 1,9 mm: self-finished and oiled

Ø from 2,3 to 7 mm: phosphated and oiled

Ø from 8 to 30 mm: self-finished and oiled

Ø from 1,5 to 30 mm: electrolytic zinc plating

Retaining rings in spring steel EN 10132 - 1/4 (DIN 17222):

Ø 1,2 mm: stacked on steel rods

Ø from 1,5 to 30 mm: loose in boxes or stacked onto steel rods (only up to Ø 12 mm)

Retaining Rings in stainless steel A4 – AISI 316 L (W.N. 1.4404) and AISI 301 (W.N. 1.4310):

Ø from 1,5 to 12 mm: stacked on steel rods

Ø from 15 to 30 mm: loose in boxes

Surface finishes on request

Upon request and for quantities / prices to be established, retaining rings DIN 6799 can be supplied with the following surface finishes:

Zinc Flake (Ø ≥ 8 mm)